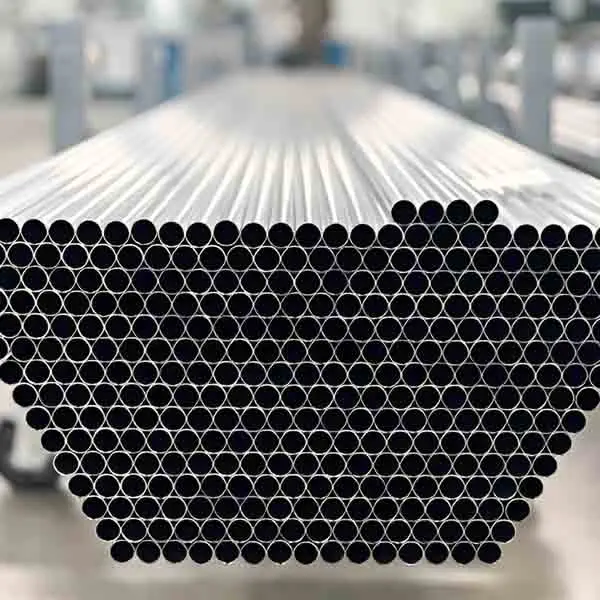

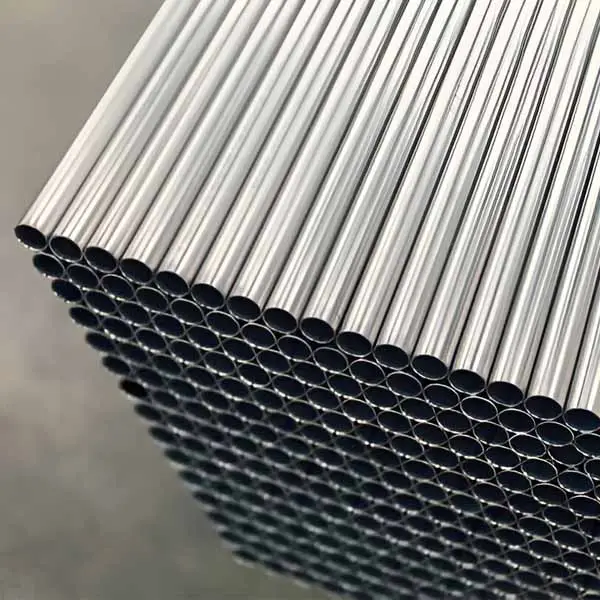

316L Mod stainless steel is equivalent to S31723, 1.4435 and X2CrNiMo18-14-3. As a leading austenitic stainless steel supplier in China, Ronsco is enowned for our exceptional production standards, strict quality control, extensive inventory, and unwavering commitment to excellence. We specialize in supplying 316L Mod stainless steel tube & pipe in various OD, ID, wall thickness and length, to meet customers' needs for different projects.

|

Available Size |

Range |

|

Outside Diameter |

3.175-325 mm |

|

Wall Thickness |

0.5-20mm |

In addition to on-demand production, we also offer an large inventory, regularly stock a variety of materials and specifications. Regardless of project size, we can all meet deadlines and deliver final products that meet or exceed industry standards.

316L Mod tube is an enhanced version of 316L tube, belongs to urea-grade austenitic stainlee steel. the key differences include slightly higher levels of molybdenum (Mo), which enhance corrosion resistance, especially against chloride-induced pitting and crevice corrosion. It may also have increased levels of silicon (Si), improving high-temperature strength and oxidation resistance.

|

Material |

Cr |

Ni |

Mo |

C |

Mn |

Si |

|

316L Mod |

16.0-18.0 |

10.0–14.0 |

2.0–3.0 |

≤ 0.03 |

1.0–2.0 |

0.5-1.0 |

Compared to 316L tube, the tensile strength and yield strength of 316L Mod tube are generally higher, providing better overall strength and resistance to deformation under load. Additionally, the material maintains good ductility with a similar or slightly better elongation percentage, making it suitable for welding and forming.

|

Material |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

316L Mod |

485 MPa (70 ksi) |

170 MPa (25 ksi) |

≥ 40% |

95 HRB |

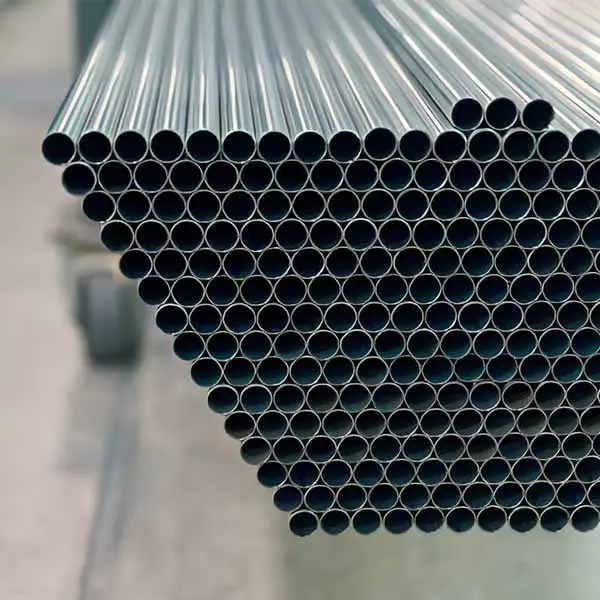

The steel 316L Mod is also known as S31723 stainless steel, widely used in industries requiring highly corrosive resistance, high temperatures and high pressures resistance, such as urea production. Thus, for 316L Mod urea-grade austenitic stainless steel tube, specific surface treatment is essential to improve its corrosion resistance and ensure the long-term stability and reliability. Common surface finishes include Acid Pickling (AP), Mechanical Polishing (MP), Bright Annealed (BA), and Electropolished (EP).

The widespread application of 316L stainless steel tube & pipe in industries such as chemical, marine, food and medical is attributed to its enhanced durability, corrosion resistance and manufacturing versatility. It is highly reliable in withstanding harsh conditions, maintaining cleanliness standards and ensuring operational efficiency to meet the demanding environments of these industries.

Ronsco is a supplier with more than 28 years of experience in the metal tubes field, we always adheres to the business phiosophy of "customer-centered", tries its best to meet the requirements of customers and pursues win-win cooperation with customers. Are you looking for a reliable tubes manufacturer ! Contact Us Now! Email: manager@ronsteel.com

Pure nickel tube & pipe composed entirely of nickel, the purity of nickel ensures a high level of corrosion resistance, making them ideal for environments where protection against corrosion is paramount.

| Grades | UNS | EN | GB |

| Nickel 200 | N02200 | 2.4060 / 2.4066 | N6 |

| Nickel 201 | N02201 | 2.4061 /2.4068 | N5 |

Nickel alloy tube & pipe is prized for their ability to excel in extreme conditions, the unique chemical composition and mechanical properties are different from traditional materials.

| Grades | UNS | EN | DIN |

| Inconel 600 | N06600 | 2.4816 | NiCr15Fe |

| Inconel 601 | N06601 | 2.4851 | NiCr23Fe |

| Inconel 625 | N06625 | 2.4856 | NiCr22Mo9Nb |

| Inconel 718 | N07718 | 2.4668 | NiCr19NbMo |

| Sanicro 28 | N08028 | 1.4563 | X1NiCrMoCu 31-27-4 |

| Incoloy 800 | N08800 | 1.4876 | X10NiCrAlTi 32-20 |

| Incoloy 800H | N08810 | 1.4958 | X5NiCrAlTi31-20 |

| Incoloy 800HT | N08811 | 1.4959 | X8NiCrAlTi32-21 |

| Incoloy 825 | N08825 | 2.4858 | NiCr21Mo |

| Monel 400 | N04400 | 2.4360 | NiCu30Fe |

| Hastelloy C276 | N10276 | 2.4819 | NiMo16Cr15W |

| Hastelloy C22 | N06022 | 2.4602 | NiCr21Mo13Fe4W3 |

Superalloys tube & pipe is a special category of advanced materials, the unique feature of this alloy lies in their ability to maintain their mechanical properties at elevated temperatures, where conventional materials would typically degrade.

| Grades | UNS | EN | GB |

| Nimonic 80A | N07080 | 2.4631 / 2.4952 | GH3039 |

| Nimonic 75 | N06075 | 2.4630 / 2.4951 | GH3030 |

Austenitic stainless tube & pipe are a prevalent type of stainless steel with high levels of chromium and nickel, these tubes exhibit remarkable corrosion resistance, particularly in acidic environments.

| Grades | UNS | EN | DIN |

| 316L | S31603 | 1.4404 | X2CrNiMo17-12-2 |

| 316L Mod | S31723 | 1.4435 | X2CrNiMo18-14-3 |

| 316LVM | S31673 | 1.4441 | X2CrNiMo18-15-3 |

| 310MoLN | S31050 | 1.4466 | X1CrNiMoN25-22-2 |

Duplex stainless tube & pipe represent a specialized category of stainless steel known for their dual- phase microstructure, combining both austenitic and ferritic phases.

| Grades | UNS | EN | DIN |

| 2205 | S32205 / S31803 | 1.4462 | X2CrNiMoN22-5-3 |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 |

| F55 | S32760 | 1.4501 | X2CrNiMoCuWN25-7-4 |

Feel free to contact us by submitting this form or use our email. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.